3D printing pen nozzle clogged – What to do?

3D printing pens are becoming more and more popular, which we think is great. However, more and more often we have messages from desperate parents that their kids' pens are clogged. We have also had these problems now and then and can say that the real problem lies elsewhere.

Heating process for 3D printing pen

A 3D pen is really nothing more than the combination of a hotend and an extruder. A little electronics and the pen is ready.

The heating process for the pens is generally as follows:

- Turn on 3D pen

- Select temperature for the existing filament

- Heating process starts.

- Nozzle reaches desired temperature. Filament can be inserted.

- Insert filament.

- Start feed and extrude filament.

Very simple, then.

In theory, not much can go wrong, right?

We will now try to explain why this is not true and how you can be happy with your pen.

The nozzle of the 3D pen is not hot enough yet

The pen is here! Now that you or your kids have waited long enough to arrive, you understandably want to get right to it. Therefore, the filament is either loaded too early or the wrong temperature is selected.

The filament is not sufficiently melted

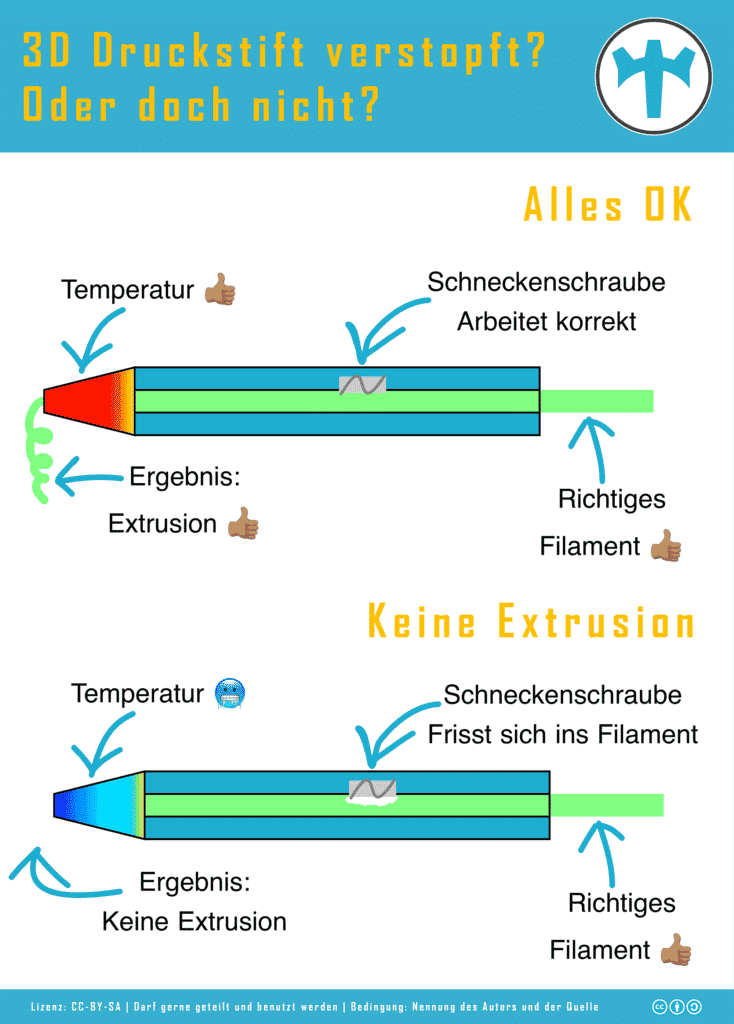

If the nozzle has not yet reached the desired temperature, or the temperature does not match the filament, the following will happen:

- The filament is pressed to the nozzle via the screw.

- The nozzle is not hot enough.

- The filament cannot flow out of the nozzle.

- You or your children continue to press the button for the feed and the worm screw thus continues to turn.

- The screw eats into the filament and no longer has contact with the filament at that point.

- The filament can now be moved neither forward nor backward by the pen.

- Nothing continues to come out of the nozzle and the first thought is like this: The nozzle must be clogged.

It is understandable that this is frustrating. Likewise, it is also understandable that some give up, return the pen, and may never address the issue again.

To ensure that this does not happen, we would at least like to clarify the situation.

But what can you do now?

Remove filament from the 3D pen

If the worm screw or any other type of screw has seized, you'll have to do it by hand.

First path to freedom – Be a little rougher

Gruff may be an exaggeration, but it certainly applied to us with a pen. Here is how you proceed:

- Please heat the nozzle to the maximum level. This way you can be sure that ABS filament and PETG filament will also be melted when you put them into your pen.

- Please wait until the nozzle is also hot enough. Some pens indicate this by means of status LEDs.

- Now press the filament into the pen from behind with your hand and operate the feed.

- This way you bring undamaged filament to the screw again and it can now grip the material.

- Filament should come out of the nozzle.

Second way – Craftsmanship needed (If the first one doesn't work)

Not a trick in that sense, but still a possibility if you have a bit of manual dexterity.

Some of the pens are relatively easy to open. With a purchase price of around €30, you're hardly taking any risks. Before you send multiple pens back and forth, you might want to open the pen and see what exactly is stuck.

As mentioned earlier, the main problem should be in the screw area rather than a clogged nozzle.

If the nozzle is actually clogged

But if the nozzle is indeed clogged, then you can go in vertically with a very thin needle.

Some nozzles are around 0.6 mm wide. So appropriately thin needles or a set for cleaning nozzles should be used. The diameters of the needles are also listed there.

* Stand: 2024-03-16 / Bilder: Amazon API