Nylon Filament – Learn all about the material

In this article you will learn, among other things, what advantages nylon filament has, in which areas it can be used and whether it can perhaps also be glued.

Nylon Filament – What's Behind It? In which areas can it be used?

Nylon is a thermoplastic and semi-crystalline plastic and belongs to the polyamide (PA) group. It is also referred to as PA 66. Other common designations are PA 6 and PA 6.6. Meanwhile, various manufacturers offer nylon filaments for 3D printing. Among the best known is probably the Taulman company, which offers the material under the designations Nylon 618, 645, Nylon 680 FDA (for the medical and food industries) and Nylon 910 for other industrial uses. These nylon filaments differ somewhat in composition, of course.

In general, polyamides are chain-formed macromolecules formed by polycondensation reaction of diamines and dicarboxylic acid. Acid amide groups serve here as pontics. The initial compounds determine which polyamide types are produced. The first number represents the number of carbon atoms in the starting molecule, the second the number of acid molecules.

What are the advantages of nylon in 3D printing?

Nylon filament is offered in a variety of colorways. Originally, however, the material is white or transparent. Therefore, it is particularly suitable for subsequent dyeing. Here, for example, you can resort to textile paint.

The 3D printing filament is characterized by the following properties, among others:

- High toughness and flexibility,

- High strength,

- High resistance to wear,

- Good chemical resistance,

- Resistance to many organic solvents, greases, weak alkalis as well as oils.

Polyamides – and thus also nylon – are often used for the production of highly stressed machine elements. Nylon filaments can be used, for example, to produce components for 3D printers and other machines.

What are the disadvantages of nylon filament?

The surface of objects made of nylon or PA 66 is attacked by acids and strong alkalis. Like all other polyamides, unprocessed nylon filament tends to absorb moisture. Although this increases the toughness, it also swells significantly. For this reason, nylon filaments in particular should be stored in a dry place.

Application examples for nylon filament

Nylon filament is very versatile. For example, this material can be used with an appropriately sized 3D printer to produce

- Gears and gear chains,

- Clutch and transmission parts,

- Maintenance-free bearings,

- Rollers,

- Housing,

- Household items including kitchen utensils such as ladles and spoons,

- Dowels,

- Screws,

- Machine parts, fuel lines, engine covers, etc. for the automotive industry.

manufacture. Of course, there are numerous other application examples, but listing them here would lead too far.

What settings are used to print nylon filament?

The detailed settings depend, of course, on the 3D printer, the composition of the material in question and the object to be produced. Therefore, these are only our empirical values. The following settings can be selected for PA 66:

- Melting temperature: 260 degrees Celsius,

- Printing temperature: About 240 degrees Celsius,

- Temperature of the heating bed: Approx. 130 degrees Celsius,

- Possible printing speed: About 25 to 40 mm/s.

Other important data:

- Nylon filament condition: Dry,

- Density: About 1.14 g/cm³,

- Elongation at break: 40/150 N/mm²,

- Glass temperature: Approx. 50 to 60 degrees Celsius,

- Yield stress: 85/50 N/mm²,

- E-modulus: 3100/1100 N/mm²,

- Hardness Shore: D84/D74

Is a heated print bed (heatbed) required in the 3D printer for nylon filament?

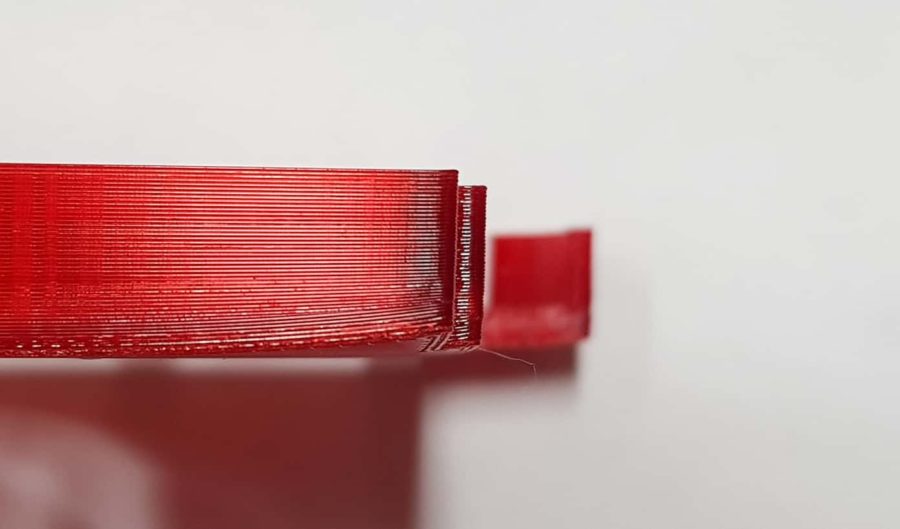

Yes, a heating bed is definitely recommended for the use of the nylon filament. To reduce the risk of warping, the 3D printer should have a closed installation space.

Can nylon filament be glued? If so, which adhesive is recommended?

Nylon filament is susceptible to strong acids and alkalis. For example, formic acid is very suitable for gluing, but also for dissolving the objects printed from nylon. The use of epoxy resin-based plastic adhesives can also be helpful. If necessary, the surface of the area to be bonded should be roughened slightly beforehand.

How can nylon filament be post-processed?

As mentioned above, nylon is a white to translucent material. Therefore, it can be dyed according to your own wishes with standard textile dye. It makes sense to color the finished object here.

Nylon filament can be very carefully polished or resanded with sandpaper. Any support structures must be removed in advance with the side cutter and other tools. Regrinding may be necessary there as well.

What should I pay attention to when storing nylon filament?

PA 66 or nylon filament quickly attracts moisture. Therefore, you should make sure that the material is stored away from moisture, but also away from sunlight. By the way, this applies to all filaments. To prevent the started rolls from drawing moisture, it is best to pack them with a few packets of silicate beads – which are often added to new leather goods and shoes by the manufacturer – in a bag, which you then seal airtight if possible.

You can label these bags (so that you know which type of filament is inside) and store them in a plastic box with a lid, or in a normal cardboard box. It should definitely be possible to close the latter. If there are small children living in your household, you should store the filament so that it is safe for children. The same applies to the 3D printer and smaller printed objects.

Where can I buy nylon filament?

Here you get a small list of nylon filament on amazon:

* Stand: 2024-03-16 / Bilder: Amazon API

If you want to check out the latest bestsellers, then you should visit the following page: