POM Filament – Learn all about it here!

The abbreviation POM stands for polyoxymethylene. This is sometimes also referred to as polyacetal, polyformaldehyde, polytrioxane or acetal. The material belongs to the thermoplastics and is white as well as partially crystalline. In order for 3D printing with POM filament to proceed to your satisfaction, it is necessary to make a few preparations. Of course, we won't reveal which ones at this point. But you will come across it in the course of this post. Of course, we hope to answer a few more questions for you with this post.

POM filament is characterized by, among other things, high impact strength, good resistance to heat, solvents, fuels and alkalis. Furthermore, it has good hydrolysis resistance. The material is also resistant to thermal and oxidative degradation. It also features reduced emissions, which makes it interesting for interior applications in automobiles.

Where can I buy POM filament?

You can find POM filament at your trusted retailer or, as always, on Amazon:

* Stand: 2024-04-21 / Bilder: Amazon API

You can find a bestseller list of POM filament at the following link:

Buy POM Filament – Current Best Sellers

What are the advantages of POM in 3D printing?

The material is suitable, for example, for the production of complicated parts for which otherwise only injection molding would be suitable. POM filament is characterized by its good chemical properties, is heat resistant and has great dimensional stability. At the same time, its abrasion resistance is very high, and the coefficient of friction is very low. Furthermore, the material has good sliding and electrical properties. It retains its toughness even at a temperature of – 40 degrees, which therefore ensures that 3D-printed objects made of this material can also be used outdoors. Due to its semi-crystalline white coloration, it is possible to color the filament in various muted shades.

If POM filament is processed at temperatures above 220 degrees or even begins to burn, it will thermally decompose. Here again the formaldehyde is formed, which develops a very irritating odor. This quickly shows that the material is processed incorrectly, which we definitely see as an advantage here, as you can react quickly in that case.

As already mentioned, the filament also has a high impact resistance. Light blows with a hammer could not harm the printed object.

What are the disadvantages of POM filament?

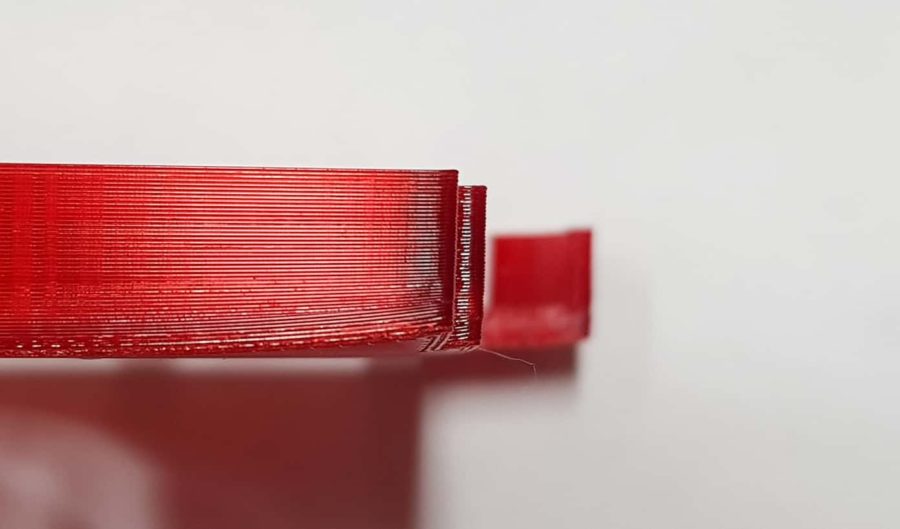

Printing with POM filament is somewhat difficult because it does not adhere well to the heating bed or printing plate. Therefore you should – if available – use a POM pressure plate. Alternatively, you can roughen your permanent printing plate well with sandpaper and then clean it with methylated spirit to ensure a better grip of the object during printing. You also have the option of applying masking tape to the printing plate and then spraying it with hairspray. This also ensures good adhesion. At the same time, it would make sense to print the first layers at a somewhat lower speed, for example 15 to 20 mm/s instead of 30 mm/s.

When you print with POM filament, the risk of warping is quite high. At the same time, you should ventilate the room very well during and after 3D printing.

Application examples for POM filament

This filament is especially good for 3D printing gears, ball bearing cages, car speaker grilles, water pump housings, nuts and bolts. At the same time, precision parts for televisions and radios, telephones, copiers and other technical devices can also be made from POM. Even clip-on toothbrushes, hinges, door and window handles and toys can be made from this material. Some of this can certainly be done with your own 3D printer.

What settings are used to print POM filament?

At this point we would like to point out that the values given here are only approximate values that we have gathered from various reputable sources. The exact settings depend, among other things, on the exact material composition – which can vary depending on the manufacturer – but also on your 3D printer. Therefore, you should tinker a bit with the fine-tuning if you have not yet achieved an optimal print result with the values given here or if you already know the weaknesses of your 3D printer.

Settings

- Pressure temperature: 190 to 205 degrees Celsius

- Heating bed temperature: about 120 degrees Celsius, switch off cooling

- Printing speed: about 30 mm/s

Is a heated print bed (heatbed) required in the 3D printer for POM filament?

Yes, a heated print bed is required. However, the cooling should be turned off, otherwise severe warping may occur. Warping may also occur when the Infill is 25 percent or more.

Can POM filament be glued? If so, which adhesive is recommended?

In order to glue objects printed with POM filament, a few preliminary steps are required. This is due to the fact that POM has a low surface energy. Therefore, the surface must be pre-treated. This is possible, for example, by means of oxidation or pickling.

If the surface is flamed with an oxygen-saturated flame, such as that emitted from a Bunsen burner, bonding is possible. To do this, the flame is passed over the surface to be bonded at a short distance and, above all, quickly.

If the bond is to hold particularly well, the surfaces to be bonded should be pickled with 85% phosphoric acid for about 10 seconds at approximately 50 degrees. After that, they must be rinsed with distilled water. In the final step, you can now bond the stained surfaces with a 2-component adhesive, for example.

How can POM filament be post-processed?

POM filament can be both ground, polished, milled, but also drilled holes. For example, for sanding you can use a belt sander, which will make the surface look like polished.

What should I pay attention to when storing POM filament?

Just as with all other filaments, you should store POM in a cool, dry place – preferably at temperatures of around 15 to 25 degrees Celsius. Furthermore, it should not be exposed to direct UV radiation. It's best to store the filament rolls you've started in plastic bags, seal them airtight, and then put them in plastic boxes with lids or in cardboard boxes. New filament rolls should be left in their original packaging until they are used for the first time.

If there are young children in your household, you should store the filament so that they can't reach it, but also talk to them about the dangers.