Infill: What is it and how does Infill affect printing?

Infill Refers to the percentage [in Prozent] of infill in a 3D printed object printed using the FDM process. An object that has an Infill 0% is hollow and one with an Infill 100% is completely solid inside.

For many cases, however, values below 70 to 80 % are sufficient, since above this value hardly any increase in stability can be expected. For fast prototypes and objects that have an upward changing shape (such as pyramids, vases, cones, sculptures, etc.), values between 0 and 10% are also acceptable.

However, if an evenly finished surface is to be on top of the object, values above 10% should be used. This is due to the fact that the smaller the proportion, the greater the distance between two walls. As a result, surfaces can begin to sag, preventing a flat surface from being created.

A larger proportion of Infill does not only mean more stability. In addition to the longer time that has to be spent on printing, the material consumption is also not to be sneezed at.

Infill and proportion: What do the different types and proportions look like?

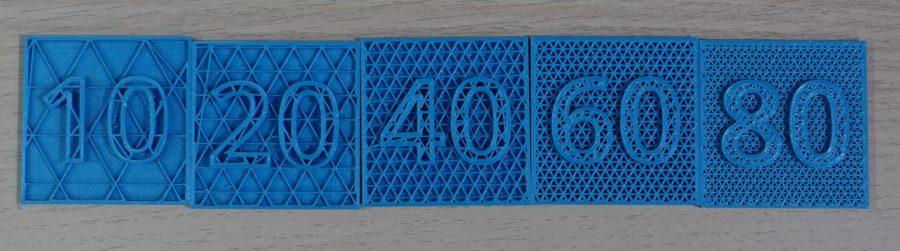

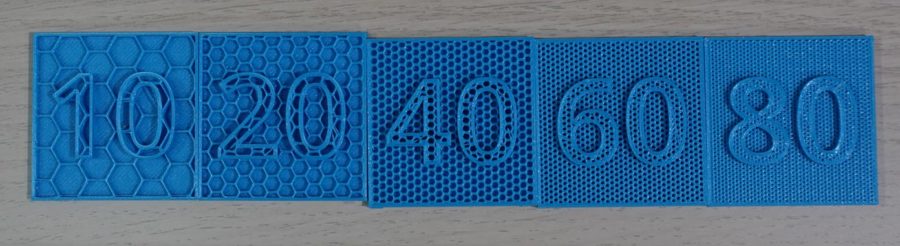

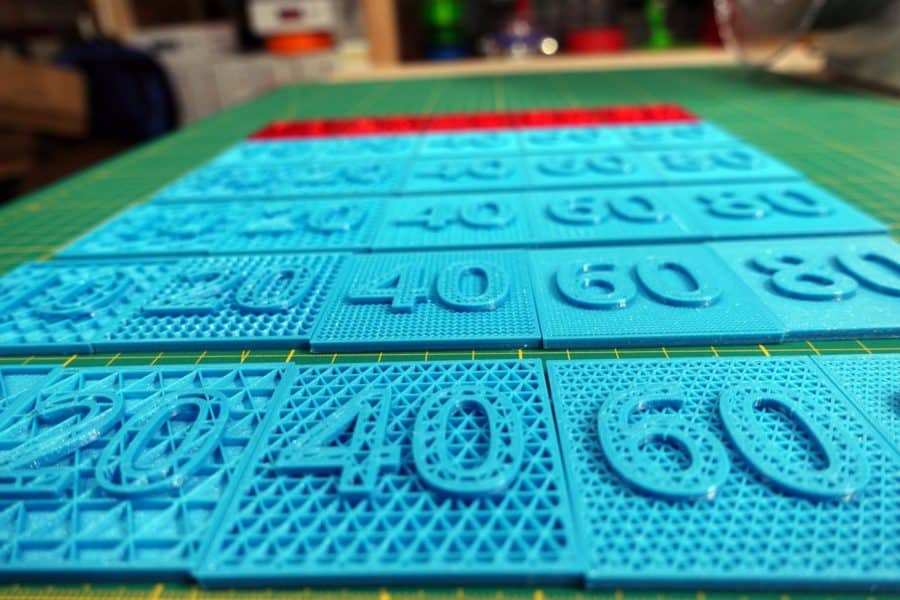

To show you the Infill and the different proportions, I created thin platelets and Infill them with a proportion of

- 10%,

- 20%,

- 40%,

- 60% and

- 80% printed.

You may also notice that in some species, from 80% or even 60%, there are already almost no spaces to be seen.

I hope this overview will help you to choose the right Infilltype and proportion 🙂

Rectilinear

Grid

Triangular

Wiggle

Fast Honeycomb

Full Honeycomb

Infill 3D printing: FAQ

Some questions are just asked more often. Here I present you the questions and my answers.