The best laser cutters for home

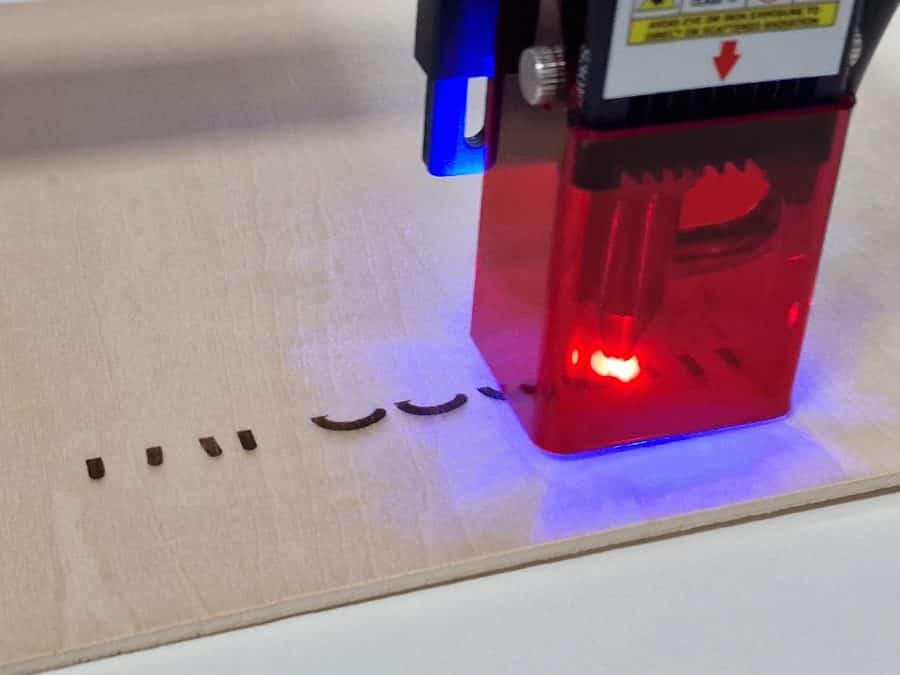

Cutting, marking, engraving – the areas of application for laser cutters are versatile. While the benefits of the products were long limited primarily to industry, this has changed significantly thanks to more flexible application options and lower prices. Those who are new to this field can choose from a variety of different devices. In the following, we will show you exactly what you should look for when buying and which are currently the best laser cutters for use in the field.

The most important in a nutshell

- Laser cutters or laser engravers are used in a variety of ways and are also being used more and more in the home

- With the devices you can cut, engrave or mark

- You can use most hobby devices for laser cutting of materials like leather, plastics or wood without any problems.

- If you also want to laser metals, you have to use special devices for this purpose

- Suitable lasser cutters for home are now available for all price ranges

The best laser cutters for home 2024

Nowadays, you can choose from different devices when buying a laser cutter. The problem: It is not always immediately obvious where the advantages and disadvantages of the individual lasers lie. For example, units with a higher power rating may be less expensive than units with a lower power rating. We have taken a close look at the market for you and listed the best laser cutters for home use below.

| Place | Name | Manufacturer | Cutting surface mm x mm | Laser type | Power (Watt) | Special features | approx. price | To the shop* |

| 1 | Laser Master 3 | Ortur | 400 x 400 | Diode | 10W | Child lock for increased safety, emergency stop, integrated WiFi | 650 | Click |

| 2 | S30 PRO MAX 20W | SCULPFUN | 410 x 400 | Diode | 20W | Compatible with wood, stainless steel, ceramic and dark stones, Windows and Mac support, high performance, engraving area expandable | 800 | Click |

| 3 | LaserPecker 2 | LaserPecker | 100 x 100 | Diode | 5W | Motion detection, emergency stop, password lock, laser warning, Windows, Mac, Android and iPhone compatible, engraving accuracy up to 0.05 mm | 1250 | Click |

| 4 | Mr Beam II dreamcut S | Mr Beam | 500 x 390 | Diode | 5W | Smoke extraction optionally available, plug & play software for Mac, Windows, Linux and tablets, integrated camera, integrated WLAN | 2600 | Click |

| 5 | S30-5W | SCULPFUN | 410 x 400 | Diode | 5W | Linear bearing, cutting range extendable | Approx. 310 | Click |

| 6 | S9-5,5W | SCULPFUN | 410 x 420 | Diode | 5,5 W | High engraving accuracy, laser filter coverage, fast focus, low price | 300 | Click |

| 7 | LaserPecker Pro Smart Laser | LaserPecker | 100 x 100 | Diode | 5W | Preview mode, password lock, automatic shutdown to protect against overheating, smart control via app | Click |

The best laser cutter for home: ORTUR Laser Master 3

The test winner with the best price-performance ratio is the ORTUR Laster Master 3. The device is available for a price of less than 1,000€ and offers an enormous performance in return. On the one hand, the assembly is quick and easy. After just a few minutes you can start working. The precision with an engraving line of only 0.1 mm is remarkable, yet the speed does not fall by the wayside at up to 20,000 mm/min. Another wonderful feature is that the Laser Master 3 can handle a wide range of materials such as wood, leather, ceramics and even metal. Although the housing is open, the laser engraver also offers an increased level of safety thanks to the child lock.

General info:

- Name: Truck Master 3

- Manufacturer: ORTUR

- Cutting surface (L x W in mm): 400 x 400

- Laser type: Diode

- Power (watts): 10

- Special features: Child lock for increased safety, emergency stop, integrated WiFi

- Advantages: Compatible with many operating systems and softwares, high precision (0.01 mm engraving line), many materials such as wood, leather, metal, ceramics, steel or paper can be lasered, simple and fast setup.

- Disadvantages: open housing

The best cheap laser cutter for home: SCULPFUN S30-5W

If you want to be especially easy on your budget, we can recommend the SCULPFUN S30-5W as the best cheap laser cutter for home use. This offers a cutting surface of 410 x 400 mm and, with a price of under €1,000, is anything but overpriced. The assembly succeeds here quickly and easily. Within less than 30 minutes, the laser cutter should be ready for use. You can use this for a variety of different materials, plus you can purchase an expansion kit for a larger cutting area if needed, and even purchase a closed housing separately. You can engrave wood, MDF, cardboard or ceramics, among other things, with the device. It is also possible to cut different types of wood, such as cherry and walnut. But also leather, bamboo, fleece or acrylic sheets.

General info:

- Name: S30-5W

- Manufacturer: SCULPFUN

- Cutting surface (L x W in mm): 410 x 400

- Laser type: Diode

- Power (watts): 5

- Special features: Linear bearing, cutting range extendable

- Advantages: easy assembly, compatible with a wide range of materials, precise in the cutting and engraving process, no wavy lines, low price.

- Disadvantages: open case (closed case sold separately)

The best laser cutter with small area: LaserPecker 2

If you only need a laser cutter with a small area, we recommend the LaserPecker 2. The cutting area is comparatively small at 100 x 100 mm. However, the laser cutter offers an engraving accuracy of up to 0.05 mm. The high speed of up to 600 mm/s with which you can engrave your objects is also remarkable. Thanks to the small cutting area, this laser cutter is overall very compact and space-saving. Moreover, thanks to a clever software, you can set it up quickly and get started after a few clicks. Among other things, security is promised by motion detection, which stops automatically when movement is detected. But the emergency stop, password lock or laser warning also offer protection.

General info:

- Name: 2

- Manufacturer: LaserPecker

- Cutting surface (L x W in mm): 100 x 100

- Laser type: Diode

- Power (watts): 5

- Special features: Motion detection, emergency stop, password lock, laser warning, Windows, Mac, Android and iPhone compatible, engraving accuracy up to 0.05 mm

- Advantages: high engraving speed up to 600 mm/s, enormously space-saving device, high engraving resolution of up to 2K, fast setup

- Disadvantages: Range of use limited to small objects

The best laser cutter for demanding home users: Mr Beam II dreamcut S

If you have higher demands, we can recommend the Mr Beam II dreamcut S as a demanding home user. The cutting area is 500 x 390 mm, which is a comfortable size, and at the same time you can set up the device in a simple and easy way. To get you started right away, there's also an extensive library of fonts and templates. The speed in the machining process is also strong, plus you can expand the set with an optional fume extractor. A real high-end device, which, however, might not be suitable for every budget.

General info:

- Name: Mr Beam II dreamcut S

- Manufacturer: Mr Beam

- Cutting surface (L x W in mm): 500 x 390

- Laser type: Diode

- Power (watts): 5

- Special features: Smoke extraction optionally available, plug & play software for Mac, Windows, Linux and tablets, integrated camera, integrated WLAN

- Advantages: easy setup, extensive library for fonts and templates, fast editing of objects possible

- Disadvantages: not suitable for every budget, maximum object height limited to 38 mm

Criteria for choosing laser cutters for home

You'll quickly find out that there are numerous laser cutters on the market to consider for use in your own home. However, you should definitely pay attention to different criteria when comparing the individual devices. We have listed these below and show you what you should check before buying.

Security

When using a laser cutter, you should definitely ensure the necessary safety in your work area. In addition, it is important to pay attention to the security features available on your device. Ideally, this provides, for example, safety glasses included. In addition, it is advisable to look for a cutter that offers a housing around the device or at least can show a housing around the laser. Other security features, such as a password lock or a child lock, increase security.

Price/Performance

In all likelihood, you will have set a firm budget for your purchase. You should try to get the widest performance range possible for this budget. Depending on the field of use, you might be able to save a bit in some places and thus perhaps sacrifice some speed for infrequent use, for example.

Laser type

Another criterion when buying the best laser cutters is the type of laser in question. The Co2 lasers in particular are characterized by high performance. However, especially in the affordable class, they require a lot of effort to be used safely and stably. It is easier with diode lasers, which is why we have focused only on these in our listing. Another advantage is that the diode has a much longer service life, whereas Co2 laser tubes can burn out from time to time.

Laser accuracy

Unsurprisingly, accuracy also plays an overriding role in the choice of the right laser. Of course, you have to dig a little deeper into your pocket for especially high accuracy. Especially when the speed should not fall by the wayside either. Compared to devices for industry, however, a few compromises can usually be accepted here for private use.

Cutting surface

The cutting surface is a very individual criterion and is mainly determined by the intended use. If you only use your device for smaller objects, a comparatively small cutting surface is also sufficient. The larger the objects, the larger your cutting surface needs to be.

Extensibility

It makes perfect sense to pay attention to the expansion options of a laser cutter before you buy it. Often, for example, you can purchase an extension kit for the cutting surface and often increase it many times over. In addition, some manufacturers also offer very special individual expansion options. A good example of this is the LaserPacker. This can, for example, also laser round objects almost without any problems, as a rotary drum is used here.

Simplicity of use

The best laser engravers are easy to use. Not every user has the same level of knowledge. Therefore, most manufacturers focus on simple use, which is possible even without much experience. However, the more versatile the options, the more complex the operation of the devices. However, especially as a newcomer, you should focus on ease of use.

Laser cutter stability

Your laser cutter should definitely be stable. If this is not the case, the operation involves a lot of dangers. It would be fatal if your laser is wobbly or unstable and thus constantly hangs the danger over the work that you or other people can be injured.

Resolution

When engraving materials with a laser, energy is absorbed. This generates heat, which in turn can lead to an enlargement and overlapping of the screen dots. To avoid this, you should look for a laser engraver with particularly good resolution. A resolution of 125 dpi is sufficient, for example, if you only want to engrave wood or glass. For metals or stamps, on the other hand, it should be possible to use at least a resolution of 600 dpi. When engraving paper or cardboard, a resolution between 500 and 600 dpi.

For whom are laser cutters worthwhile?

Laser cutters are becoming more and more popular and are being used in an increasing number of applications. Typically, of course, in the industry or smaller companies to either cut their own products or add a logo or something similar. In addition, the laser cutters are also ideally suited for use in educational institutions. The students of higher age groups could gain their first practical experience with these and thus, for example, create their own awards, name tags or similar.

For the hobby sector, the purchase of a laser cutter is also worthwhile. Those who are involved in model making at home, for example, will probably appreciate the laser cutters after a short time.

Safety aspects when using laser cutters – What to look out for?

When using laser cutters, you should of course take certain safety precautions. As a minimum recommendation, we can advise you to open the window during work and ensure good ventilation. In addition, you should wear safety goggles, which are already included in many of the sets. It is best to ban children and pets from the respective study.

If you want to play it safe and create a top solution in the field of security, you should focus on additional investments. For example, you can purchase an additional fume hood or filter that you can use in addition to precautions such as an open window.

Laser cutters for home: what materials can they cut and engrave?

Laser cutters for the home are often underestimated. In many cases, these are truly high-performance devices that allow you to cut and engrave a wide variety of materials. Please note that there can be differences between the individual materials. For example, most home laser cutters can easily cut bamboo, but not engrave. Below we have listed a few typical materials that you can easily cut or engrave at home with most laser cutters.

- Wood

- MDF

- Plastic

- Cardboard

- Paper

- Leather

- Printed circuit board

- Stainless steel

- Ceramics

- Dark stone

- Bamboo

- Fleece

- Arcyl plates

- Metals

Advantages and disadvantages of laser cutters for home users

Laser cutting for home users brings both advantages and disadvantages. We have listed the most important arguments of the pro and con sides here.

Applicable to many materials

Nowadays, you can use your laser cutter for your own four walls in many different ways and for different materials. Most devices can effortlessly process materials such as wood, acrylic or even plastics. Some laser cutters can even cut through metal with their power. In other words, you can work with almost any everyday material you can think of.

Engraving and cutting possible

Laser cutters by “nature” offer the possibility of being used in two senses. On the one hand, you can use them to cut different materials and thus cut through them completely. On the other hand, you can also simply engrave individual materials. So the use is entirely up to you.

Safety precautions are to be taken

If you want to work with a laser engraver, you can't just get started. Instead, certain preparations and safety precautions are required. You should provide good ventilation or even install an additional air filter. In addition, children and pets should be removed from the study.

Acquisition costs can be high

Depending on the requirements and desired functions, the initial cost of laser cutters can be enormous. If you rely on high performance with a fast mode of operation and great precision, costs of several thousand euros can quickly become due here. If you can do without certain components and functions, you can also save a lot of money.

Conclusion: Exploit creative possibilities

With a laser cutter, you have several options for processing different materials. You can not only cut them, but also engrave and mark them. The individual devices also usually offer various protection mechanisms to keep you and your loved ones safe from potential risks. Which device is the best solution for you should not depend on your gut feeling. Instead, a precise comparison of the individual models together with their advantages and disadvantages is definitely recommended.

Frequently asked questions about the best laser cutters

More buying guides: