The best dual extruder 3D printer: multicolor 3D printing

The dual-extruder 3D printers inspire many users. No wonder: the devices bring with them a number of advantages and, for example, make it easy to combine different printing materials. However, in most cases, dual extrusion also increases the complexity of a printer and its settings. In the following, we will show you the best dual extruder 3D printers and tell you what you have to look out for when buying one.

The most important in a nutshell

- Dual extruder 3D printers are devices that are equipped with two or more extruders

- Differences are made between independent dual extruders (IDEX system) and dual extruders on one rail.

- Particularly important when choosing the right dual extruder 3D printer are the ease of calibration and the right Slicer

- Nowadays, many printers can be called high quality and high performance dual extruder 3D printers

- With our help, you can find the best dual extruder 3D printer 2022 and get important tips for your next print.

The best dual extruder 3D printer 2024

To provide you with a quick overview, we have listed the current best dual extruder 3D printer 2022 here in our table:

| Place | Name | Manufacturer | Filament diameter | Installation space | Print resolution | Special features | approx. price | To the shop* |

|---|---|---|---|---|---|---|---|---|

| 1 | S3 | Ultimaker | 2.85 mm | 23 x 19 x 20 cm | 0.60 mm | Auto-bed leveling, front window can be closed, intelligent filament sensors, integrated webcam, intuitive operation | 4.700 € | Click |

| 2 | Sigma D25 | BCN3D | 2.85 mm | 42 x 30 x 20 cm | 0,50 mm | High precision, dual extruder with IDEX system, intuitive touch screen, quiet printing process. | 4.150 € | Click |

| 3 | Creator 3 V2 | FlashForge | 1.75 mm | 30 x 25 x 20 cm | 0.40 mm | USB, WiFi and cloud support, automatic print stop in case of filament problems, built-in HD camera, up to 300 degrees printing temperature. | 1.999 € | Click |

| 4 | S5 | Ultimaker | 2.85 mm | 33 x 24 x 30 cm | 0.60 mm | Compatible with over 200 materials, large build envelope, advanced ABL system, metal 3D printing possible | 7.550 € | Click |

| 5 | M300 Dual | Zortrax | 1.75 mm | 26,5 x 26,5 x 30 cm | / | Blackout system, dual extrusion and single extrusion possible, capacitive sensor for calibration of the build platform, integrated camera | 5.499 € | Click |

| 6 | A20M | Geeetech | 1.75 mm | 25,5 x 25,5 x 25,5 cm | 0.10 mm | LCD display, WLAN optional, dual extruder with one nozzle, compatible with many filament types | 279 € | Click |

| 7 | Creator Pro 2 | FlashForge | 1.75 mm | 20 x 14,8 x 15 cm | 0,50 mm | Touchscreen display, heated build platform, compatible with multiple filaments, dual extruder with 2 nozzles | 769 € | Click |

| 8 | Flow IDEX | CraftBot | 1.75 mm | 42,5 x 25 x 25 cm | / | 2 print heads, up to 300 degrees print temperature, up to 110 degrees print bed, WLAN compatible, large installation space | 3.959 € | Click |

| 9 | A10M | Geeetech | 1.75 mm | 22 x 22 x 26 cm | / | Dual extruder with 2 input and one output, LCD screen, high printing speed, filament sensor. | 209 € | Click |

The best dual-extruder 3D printer: Ultimaker S3

Our test winner is the Ultimaker S3. This dual-extruder 3D printer offers you easy print bed leveling with auto-bed leveling, ensuring tremendous precision on all prints. In addition, the installation space is large enough for most users, and operation is also intuitive and simple. Other special features include the closable front screen or the integrated webcam. This makes it possible for you to track the printing process at any time.

General info:

- Name: S3

- Manufacturer: Ultimaker

- Installation space (L x W x H in mm): 230 x 190. 200

- Maximum print resolution (microns): 60

- Special features: Auto-bed leveling, front window can be closed, intelligent filament sensors, integrated webcam

- Advantages: Service package can be booked on request, intuitive operation

- Disadvantages:

The best cheapest 3D printer with dual extruder: Geeetech A20M

The Geeetech A20M is an FDM printer that allows you to use filaments with a diameter of 1.75 mm. The printer's installation space of 255 x 255 x 255 mm is sufficiently large and noticeably larger in both the x and y directions than its “smaller” brother, the Geeetech A10. You can heat the heating bed up to 110 degrees Celsius, the extruders bring up to 250 degrees, so you can process most filament types without any problems. For a relatively low price, you also get a clever filament sensor, and you can upgrade with a BLTouch sensor for slightly less manual leveling, among other things.

General info:

- Name: A20M

- Manufacturer: Geeetech

- Installation space (L x W x H in mm): 255 x 255 x 255

- Maximum print resolution (microns): 10

- Special features: LCD display, WLAN optional, dual extruder with one nozzle, compatible with many filament types.

- Advantages: Low price, large installation space, ABL optionally available

- Disadvantages: Kit, low layer resolution

The Best Premium Dual Extruder 3D Printer: Ultimaker S5

If you are looking for a real premium device, we can recommend the Ultimaker S5. This offers you a large installation space of 330 x 240 x 300 cm and also a high maximum print resolution of up to 60 micrometers. Ultimaker is known for the high-quality materials of its printers, as well as for the easy operation by means of modern displays. The S5 also features an integrated webcam for tracking print jobs and offers advanced auto-bed leveling. This high-end printer is also compatible with more than 200 materials and enables metal 3D printing, among other things.

General info:

- Name: S5

- Manufacturer: Ultimaker

- Installation space (L x W x H in mm): 330 x 240 x 300

- Maximum print resolution (microns): 60

- Special features: Compatible with over 200 materials, large build envelope, advanced ABL system, metal 3D printing possible.

- Advantages: Heating bed up to 140 degrees, high print resolution, WiFi connection, integrated webcam, quick setup and easy touch control.

- Disadvantages: High price

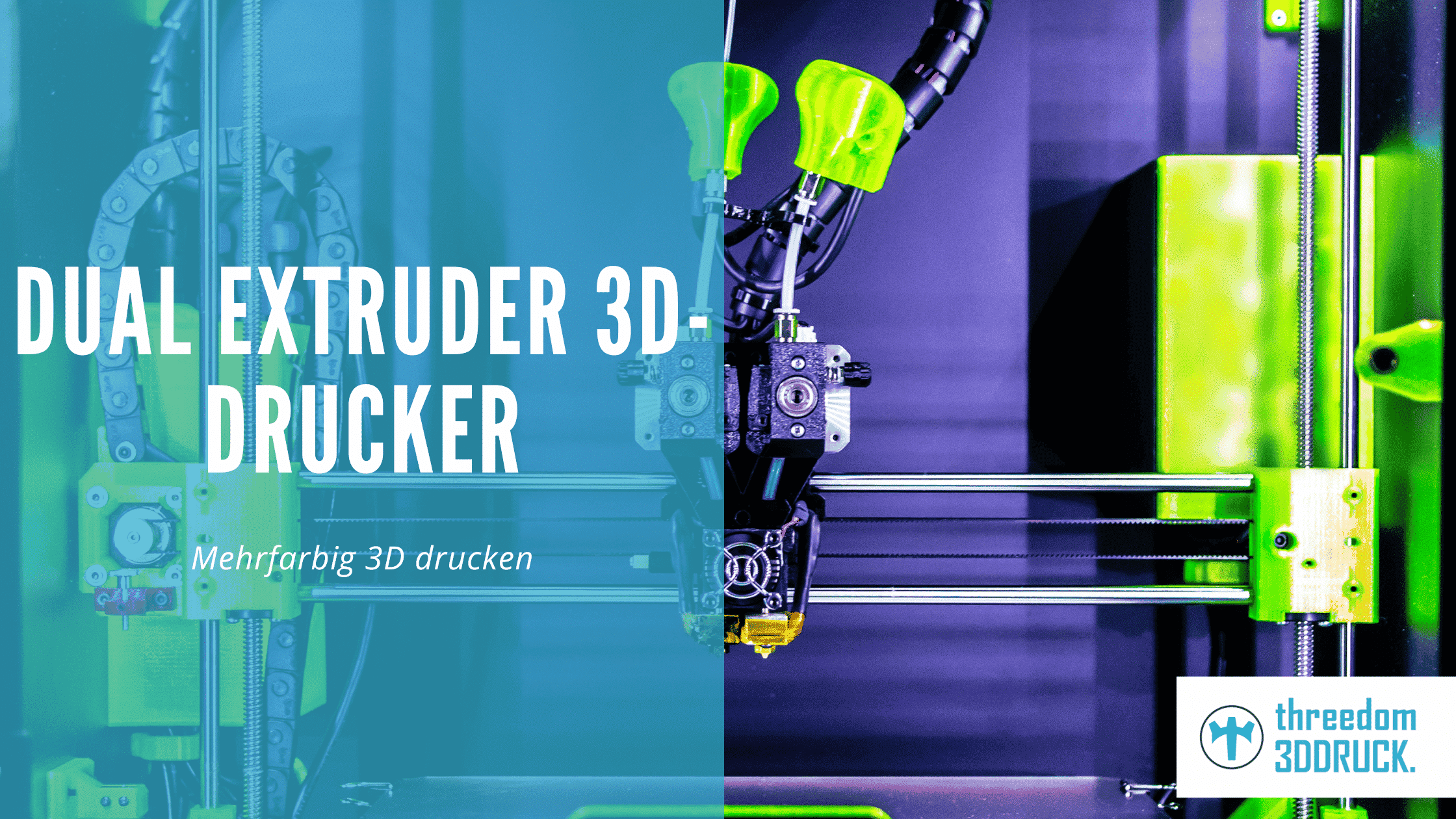

What is a dual extruder 3D printer?

A dual-extruder 3D printer is a printer that can process multiple print materials at the same time. The process is called dual extrusion and gives users much greater latitude with their equipment. For example, thanks to dual extrusion, multicolor printing can be accomplished or even two objects can be printed in parallel at the same time.

By the way, this technology is not entirely new. The CTC Bizer, a dual-extruder 3D printer that was a clone of the Makerbot Replicator 2, was launched more than five years ago. However, this did not really catch on, as calibration in particular presented challenges. This changed permanently with the Ultimaker 3, which made dual extrusion much more user-friendly.

How does multicolor 3D printing work?

Multicolor 3D printing works on a simple principle. A Dual Extruder 3D printer is equipped with two extruders, which can thus process two filaments within one print job. For example, you can use one extruder to create the object material while using the other extruder to create the support material. Or you can use the different extruders to create multicolor prints. You do not have to change the different colored filaments in a dual-extruder 3D printer.

Types of multicolor 3D printing

In multicolor 3D printing, a general distinction can be made between two types: The Independent Dual Extruder System (IDEX) and the Dependant Dual Extruder System.

IDEX Independent Dual Extruder System

In the Independent Dual Extruder System, the dual extruders are separate from each other and also operate completely independently. For example, you can print two objects at the same time or use PVA as a substrate if you want to create more complex objects. In many cases, the nozzles are simply cleaned using silicone disks during printhead replacement. This prevents too much filament material from being found on the surface of the print.

Dependant Dual Extruder System

In addition to the so-called IDEX system, the Dependant Dual Extruder System is also used for multicolor 3D printing. In this case, the dual extruders are not separate from each other, but are located on one rail. The big advantage in this case is mainly the speed.

Selection criteria for a 3D printer with dual extruder

At first glance, many 3D printers with dual extruders come into question. Of course, the personal requirements and expectations you have for your device are crucial. Apart from that, you should also keep a few general selection criteria in mind. We will now explain to you in more detail what these are and what you have to pay attention to.

Easy calibration of the dual pressure

Dual printing has come to fame and glory especially in the recent past. This is because a much easier calibration is now possible. Just a few years ago, this was probably the greatest challenge and ultimately ensured that this process was only able to establish itself belatedly. Even today, however, you should definitely check which calibration options are offered to you and how easy you can make the settings when buying.

Software optimized for dual printing

The second major criticism was the Slicer, which for many years was not optimized for dual printing at all. Here, too, a lot has changed in the meantime. Nowadays, many devices offer suitable software for dual printing, making it much easier to implement even for novices. If you don't find such software with your printer, you might face a noticeable challenge, at least as a beginner.

Price/Performance

The price-performance ratio should be checked for each product. This is also the case with dual-extruder 3D printers. In recent years, the price of high-performance equipment has decreased significantly due to advanced development. Good devices are already available for “small” money. Nevertheless, we advise against buying too cheap. In this case, there is a risk of inferior quality, which may be associated with subsequent costs.

Heated print bed

Your dual extruder 3D printer should definitely have a heated print bed. In the best case, you can also flexibly exchange this and easily remove it from the device. This will also help you with cleaning and maintenance. Incidentally, the maximum temperature of the print bed is also not entirely unimportant. This should be able to reach at least 100 degrees Celsius.

Easy maintenance

Every 3D printer needs maintenance sooner or later. This is the only way to ensure that your device will continue to perform its services faithfully and reliably even after a long time. Maintenance can be a bottleneck in the search for the best printer. If you do not want to set yourself unnecessary tasks, you should pay attention to the simplest possible maintenance. In this case, it is also helpful if there is competent support available or if you can rely on a large community.

Spare parts available

Finding replacement parts doesn't have to be a challenge. However, it still is for many devices. We therefore advise you to take a look at how and where you can obtain possible spare parts before you buy. Depending on the printer and manufacturer, this is sometimes easier, sometimes more complicated.

Installation space

You should pay great attention to the build space of your dual extruder 3D printer. Due to the additional extruders, the installation space decreases a little compared to classic 3D printers with only one extruder. This is especially the case for printers with the INDEX system, as this takes up a comparatively large amount of space. Depending on the desired size of your print objects, you must therefore be particularly attentive here.

Who are 3D printers with dual extruders suitable for?

3D printers with dual extruders are good for you if you want to implement slightly more complex prints. For example, if you often print two-color or multicolor objects or want to produce complex geometry using soluble support structures. In these cases, a dual-extruder 3D printer is most likely the best choice for you. If, on the other hand, you want to focus primarily on simple prints, a single-extruder printer will suffice in many cases.

Advantages and disadvantages of dual extruder 3D printers

The dual-extruder 3D printers offer some real advantages. Especially if you like to print complex and multicolored materials, these make the process noticeably easier. You can use multiple colors without changing materials, and you can also use completely different materials. Depending on the dimensions of the objects, you can even print two smaller versions in parallel.

A possible disadvantage is that the installation space is steadily reduced by the additional extruders. So finding dual-extruder printers with a particularly large installation space can be a challenge. Likewise, there is a risk of oozing or that you need a little more time for adjustment due to the uneven material properties. Also the slicing is usually a bit more complicated, but the modern software of the manufacturers can help you a lot here.

Advantages

- Use multiple colors without changing materials

- Different materials, for example for support and object material, can be used

- Different nozzle diameters for different object areas and reduced printing time

- Small objects partially printable in parallel

Disadvantages

- Print volume decreases due to additional extruder

- Slicing may be a bit more complicated

- Risk of ink contamination (oozing) present

- Longer adjustment time for unequal material properties

Upgrade kits: The alternative for 3D printers with dual/multiple extruders

Various upgrade kits have turned out to be an interesting alternative to 3D printers with dual extruders. With these, you can easily upgrade your printers. A few particularly interesting kits are briefly presented below.

Prusa MMU2S Upgrade for i3 MK3/2

The Prusa MMU2S Upgrade for i3 MK3/2 printers is the second generation of printer-specific multi-material add-ons from Prusa. You can print with this kit with up to five filaments at the same time, so that even particularly complex and very colorful objects come into question. Compared to the MMU1, the MMU2S has been fundamentally redesigned and uses a brand new filament loading mechanism, filament jamming is prevented by a Finda sensor and built-in blade.

BIQU Dual Color Upgrade Kit for BIQU B1 + BQ

For dual color printing on the BIQU B1 and the BQ, you can use the Dual Color Upgrade Kit from BIQU. This is a dual printhead with two inputs and one output. So you can print two different colored filaments. Thanks to the modular design of the kit, assembly of the extruder and hotend is simple. In addition, the upgrade kit is compatible with other functions such as a dual Z-axis.

Palette 3 Pro

While the two upgrade kits mentioned so far are provided printer specific, you can use the Palette 3 Pro for different 3D printers as an upgrade. Up to eight different filaments can be processed with this kit. Compared to the Palette 3 2S, the 3 Pro prints about 20 percent faster, and compared to the Palette 3, it is at least about ten percent faster. In addition, the upgrade kit is equipped with a Canvas Hub and also makes it possible to manage prints in the cloud.

Small tip: If you want to check if your printer is compatible with Palette 3 Pro, you can check the official list of compatible printers here.

Conclusion: Find the best 3D printers with dual extruder easily

3D printers with dual or multi-extruders are very popular nowadays. In many cases, the manufacturers have noticeably improved their devices in this respect and have thus been able to eliminate the “teething troubles” of the past. However, there are still some significant differences between the devices. If you want to find the best 3D printer with dual extruder for you, you should therefore take a close look at the features and functions before buying. Furthermore, you should question what requirements you have for your device. This will also help you to choose the right printers.

Frequently asked questions about printers with multiple extruders

Feel free to send me your questions about 3D printers with dual extruders and I'll answer them here for everyone.

More buying guides: